Navigation Menu

[expand all...]

[COLLAPSE ALL...]

|

Expand All

Compress All

- General Information

- The Solitec spinner is used for depositing a uniform layer of a material on a wafer. It can be used for photoresist or other materials.

- Equipment Specifications

- Variable speed up to 6000rpm

- Supports substrates up to 9" in diameter

- Operating Instructions

- General Operating Information

- To use the spinner, the house vacuum must be on.

- Special care should be taken when using SU-8. It is not good if it gets all over.

- Also take care that nothing can go down the opening for the chuck or else the inner workings can get messed up.

- Startup

- To start out, the switches should all be in the off position. The speed knob should be at zero.

- Cleanroom wipes should be placed around the bowl of the spinner to help keep it clean.

- Place wafer on chuck

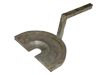

- Use the metal wafer holder to position the wafer on the chuck. There is a groove

in it so it can slide under the chuck in order to center the wafer on the chuck.

- When the wafer is in position, switch on the vacuum and carefully slide out the wafer holder.

- Start Vacuum and motor

- Switch on the power and the motor for the spinner.

- The speed of the spinner may be controled by the knob to the right of the power switch.

- No accurate speed control is available for this spinner, so it is generally used only for cleaning the wafers.

|